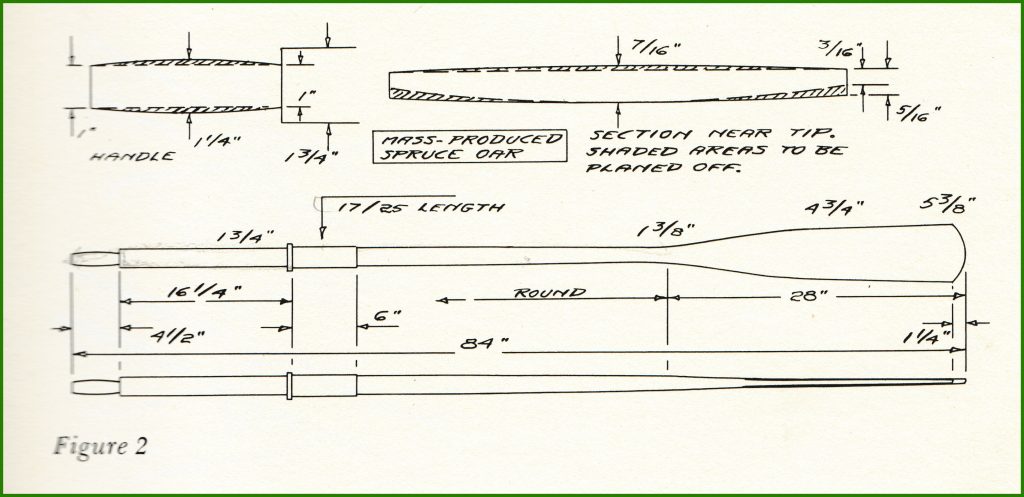

In his book, “Small Boats”, Phil Bolger, in his essay on rowing, describes how to modify an ordinary mass production oar to make it more pleasant to use.

With the current Covid-19 situation, maintaining one’s equipment may be the best way to self-isolate.

Twenty-five years or so ago, I built a glued-lap Defender design from Phil Bolger’s “Small Boats” book. My good friend, Chris, bought the oars for the boat. i still have them, even though the boat is long gone. (retired to Half Moon Bay, Sunshine Coast, oarless!)

The oar blades:

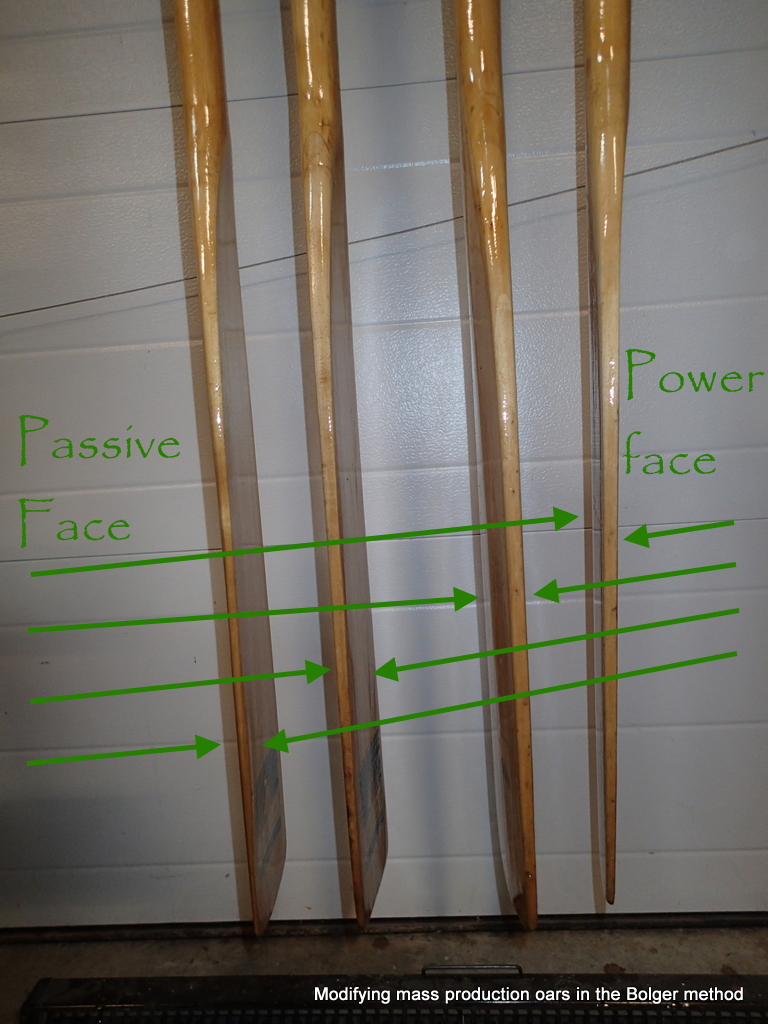

What I am going to do is to flatten the “power” side of the blade using my grinder and a sanding disk.

The sanding disk will slightly cup the power face of the oar.

I continue to remove material using the sanding disk until I have sanded to the edges of the blade.

As I am slightly cupping the blades, I will not remove any material from the passive face of the oar.

This is the passive face of the oar…untouched except for a little sanding.

To put the logos on the oar blades, I print them onto Onionskin paper and then varnish them on.

The handles (unvarnished) rest on one of the steps and the leathers (also unvarnished) rest on another. There is actually some sun today.

The rains have begun…I will put ten or more coats of varnish on the oars, one coat a day. Usually I put on more coats until I run out of varnish. (It always seems to harden up in the can, might as well use it) This time I have bought a big can of varnish, so only ten coats.

When the Pandemic is over I will take the oars out for a spin…may be a while.

My next project is to build the Herreshoff Pram from John Gardner’s book, “Building Classic Small Craft”, pages 18 to 31.

Good Rowing to you and stay safe,

Mike